Die casting companies rely on our tooling to make great die casting parts. Die Casting Tooling quality and standardization play a critical role in achieving repeatable, high-quality parts at competitive costs. One commonly used standard in North American die casting operations is the “DME 12×15 unit tooling format”. This tooling size, defined by the dimensions of the die shoe, offers a balance between flexibility, durability, and compatibility with a wide range of die casting machines, making it a popular choice for small- to medium-sized components.

Die Casting Part Prices

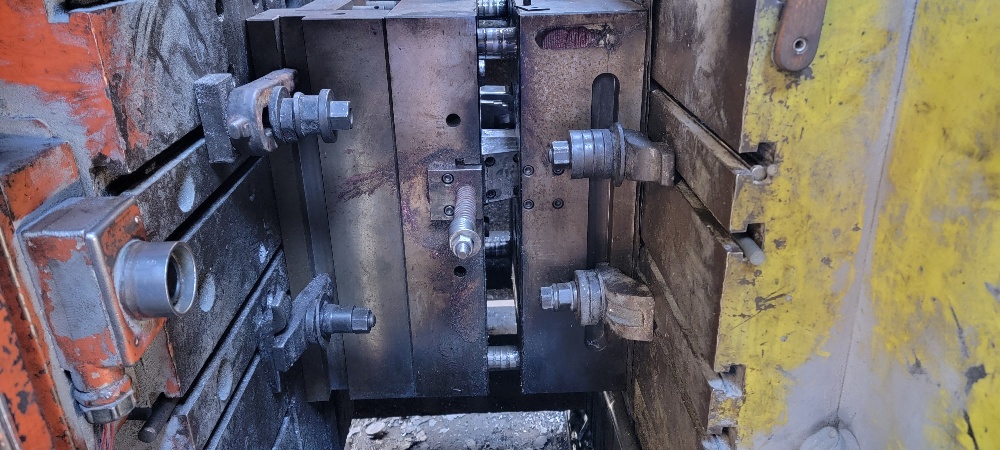

The 12×15 designation refers to the nominal dimensions (in inches) of the die shoe supplied under the DME (Detroit Mold Engineering) standard. DME unit dies are pre-engineered tooling bases that include standardized leader pins, bushings, ejector housings, and clamp plate configurations. By using a unit tooling approach, die casters can significantly reduce design time, machining costs, and lead times compared to fully custom die sets.

One of the key advantages of DME 12×15 unit tooling is its modularity. Inserts, cavities, cores, and slides can be designed to fit within the standardized die set, allowing components to be changed or refurbished without replacing the entire tool. This is especially valuable in high-volume die casting environments where wear, erosion, or design revisions are expected over the life of the program. The ability to swap inserts minimizes downtime and extends tooling life.

From a machine compatibility standpoint, the 12×15 size is well-suited for small to mid-tonnage die casting machines, typically in the range of 200 to 400 tons, depending on alloy, part geometry, and projected area. This makes it ideal for aluminum and zinc die casting applications such as automotive brackets, electronic housings, consumer hardware, and industrial components. Its compact footprint also helps optimize thermal control, reducing cycle times and improving dimensional stability.

Another benefit of DME unit tooling is predictable quality and alignment. Because leader pin locations, ejector systems, and plate thicknesses are standardized, die alignment is consistent across builds. This reduces the risk of flash, uneven wear, and premature failure. For tooling engineers and maintenance teams, familiarity with DME standards simplifies troubleshooting and repair, as replacement components are readily available from multiple suppliers.

Cost efficiency is a major driver behind the continued use of 12×15 unit dies. Initial tooling costs are generally lower than custom die sets, and long-term maintenance expenses are reduced through standardized spare parts. Additionally, many die casting shops already stock DME-compatible components, further lowering inventory and procurement costs.

In summary, DME 12×15 unit tooling offers a proven, economical, and flexible solution for die casting manufacturers. Its standardized design supports faster tool builds, reliable performance, and efficient maintenance, making it an excellent choice for programs that demand consistency, scalability, and cost control. For many die casting applications, the 12×15 unit die remains a practical and dependable tooling standard.

|

Kinetic Die Casting Company, Inc. 6918 Beck Avenue, North Hollywood, California USA 91605 E-mail sales@kineticdiecasting.com (818) 982-9200 California Die Castings – Die Casting Photos – Technical FAQ – Die Casting Prices – Kinetic Die Casting Company What is Die Casting ? – Why Use Die Casting – Kinetic Abilities – Die Casting Offshore ? – Sand casting prices and die castings – Die Casting Tooling – Kinetic Newsletter |